Reverse Engineering Services is the imperative piece of the item

advancement cycle where organizations pick contender items to break down on the

advances utilized by the present items in the market. To do as such

organizations try to re-appropriate such work.

Also, Reverse Engineering Services is the way toward making enhancement in the

present results of a similar organization.

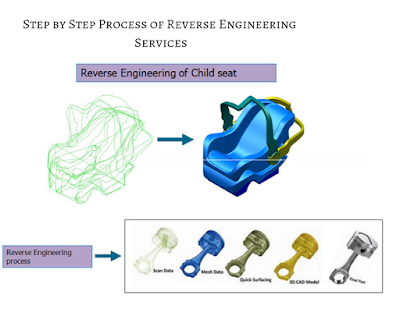

Reverse Engineering Services alludes to the procedure of re-making

structure illustrations by taking estimations as well as outputs of the part

itself.

It's a straightforward, two-advance procedure:

1) examine the article,

2) make a 3D model of the article.

Utilizing 3D inspection procedures and CMM technique, we

help you convert your current gear and item plans into editable CAD creation

illustrations and models to supplant the exhausted parts. Our CAD masters help

you archive plans in type of 3D models in Solid Works, Solid Edge, Auto CAD or

some other CAD stage.

Reverse Engineering Services utilizing 3D filter information

is the most productive and successful approach to create a CAD show from a

physical article that has any sort of mind boggling or freestyle shape. While

utilizing customary estimation procedures, for example, calipers to figure out

these mind boggling surfaces can be troublesome or even unthinkable, 3D laser

checking sparkles – actually! Output information can be transformed into a

model speaking to it's as-fabricated shape or to coordinate unique

as-structured highlights – including parametric ones.

3D inspection isn't the "simple catch" that many

think it is. The most basic advance in the Reverse Engineering Services procedure

is the demonstrating span performed by the applications engineers. Thusly, the

reverse engineering procedure can be

very perplexing and is subject to the aptitude and mastery of both the

architects taking every necessary step and those dealing with the venture. The

better the designers, the better the outcomes.

Reverse Engineering ventures require a dimension of precision that

you essentially can't settle on. That is the reason designing groups lean

toward Creaform as their go-to accomplice for all their retrofitting

necessities.

Some Related Topics:

Gocator 3D Smart Sensors

CMM Inspection Services

3D Inspection Services

Concept Designing

3D CAD Modeling Services